For some years, the destination of one of the most consumed plastics in the world (PET) is no longer a trash can. Now, there is the possibility to give it an opportunity to start a new cycle of consumption for countless times. This is what we do as Origin and at the Enkador manufacturing plant.

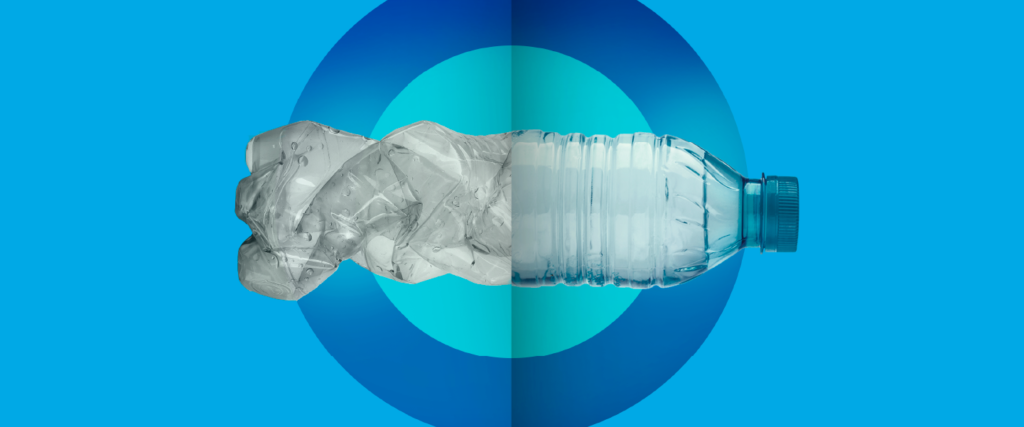

One of the most important characteristics of PET plastic is that it is 100% recyclable, and is not only capable of giving rise to materials such as textile fibers, but also a fully functional bottle for the food industry and for the consumer. This process is a great contribution so that circular economy continues to grow in our country, and that presence of unused waste is significantly reduced in the environment.

How is this process? We’ll tell you then:

1. Collection of raw material

Our main input is PET plastic, which is consumed daily in beverage bottles and plastic containers. We obtain it thanks to the work of our network of grassroots recyclers, who efficiently manage waste in each of their areas, to ensure that the raw material is in optimum condition to be transformed at the plant. Our goal as Origin is also to educate the community to facilitate the collection of waste that can be recycled, and, therefore, contribute to the work that grassroots recyclers do in a daily basis. In this sense, it is essential to recognize which are the PET bottles (identified with the number 1 at its base) and to separate them correctly.

2. Bottle crushing and purification

Once the collected bottles arrive at Enkador, the crushing or grinding process begins to turn the PET into flakes that are subsequently washed and purified. The plant operates with sophisticated, state-of-the-art equipment that guarantees the highest quality, safety, and purity of the new bottle once it reaches the consumer.

3. Obtaining resin and the preform of the new bottle

The washed and purified flakes enter the resin conversion process, a transparent and pasty substance that is very common for the manufacture of plastics. At Enkador, the flakes are transformed into food-grade rPET resins, that is, suitable for the new bottles to house food and beverages. Later, the resin goes to the last transformation process: the preform, which is the initial shape that the new bottle will have.

4. Distribution of the new bottles

The bottles produced in Enkador are capable of reviving over and over again through recycling, thanks to the application of ecodesign, which is based on the production of sustainable and environmentally friendly materials. Our bottles are used by renowned brands such as Pony Malta, San Felipe and Splendor. Our commitment is reflected in this process, in which we produce more than 500,000 recycled bottles daily, supported by the work of more than 5,600 recyclers, and which has resulted in 992,450,115 bottles recovered from mountains, oceans, and rivers, so far.